Once the engine has made its power, it is the exhausts job to help expel the gases produced, also in road cars cancelling out the sound of the engine. The sound the engine produces is a combination of high and low pulsating pressure waves. These wave pulses make their way through the exhaust pipe, at the speed of sound and ultimately the exhaust system is trying to cancel out each wave produced with another. This is the job of a standard road car´s exhaust system.

This cancelling out is a term called destructive interference and it is possible for two opposing sound waves to actually cancel each other out. When one sound wave is at it's maximum peak and the other at it's minimum trough, they effectively create a neutral balance. In a real world situation this is almost impossible to achieve and not all of the ever changing sound wave frequencies, will be able to be cancelled out. This is due to the nature of the different engine Revs and sound waves produced in a dynamic manner.

This process is a delicate compromise of power, noise and emissions. In different parts of the world we have ever increasing legislation to help combat increasing Green House effects and CO2 emission levels. During this process in production cars, the noise and CO2 levels take top priority and power is effectively sacrificed. A device called a Catalytic Converter is used to help break down some of the dangerous chemicals produced by the engine.

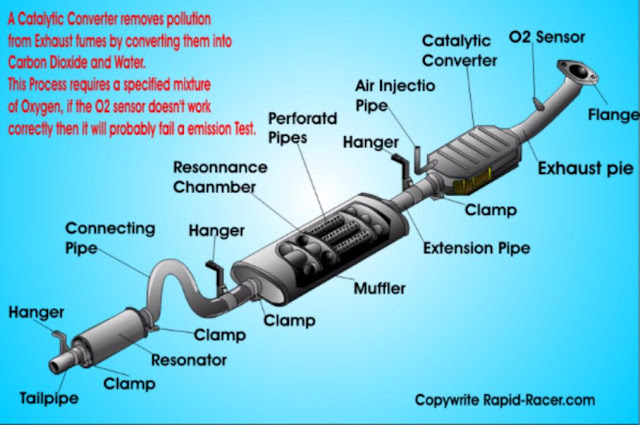

The Exhaust system as a whole is normally broken down into a few individual parts as this technology has under gone multiple development work over the decades, both in terms of performance gains and ever increasing environmental responsibilities.

Exhaust Manifold:

The exhaust manifold is connected to the cylinder head and takes each cylinder's exhaust fumes and combines it into one pipe. The manifold can be made of steel, aluminium, stainless steel, or more commonly cast iron.

By upgrading to a sports 4-2-1 (four into two into one) or 4-1 (four into one) exhausts, it is possible to release some of the otherwise wasted power and improve drivability, torque and horsepower. The exhaust manifold is one of the most important parts that controls the output of an engine.

Endless amounts of money on tuning your engine internally can be wasted if the exhaust manifolds design does not complement the overall goal of the engine design. Your engine may not produce the power you expected, or exactly where you wanted, it may move the torque band into a different part of the rev limit or power band. It is advised that a good matching of the exhaust system and manifold, compliments the engine target characteristics.

Exhaust Downpipe:

Connecting all of the above exhaust devices parts is the exhaust piping, this carries the gas through the system out to the tail pipe. Exhaust tubing is usually made of steel or aluminium steel tubing and the system carries away the gases created when the fuel and air are burned in the combustion chamber.

When upgrading the exhaust system, the kit will contain these pipes and the increased diameter/quality material means more flow and better rust repellent properties.

Catalytic Converter:

The main function of this component is to converts dangerous carbon monoxide and hydro-carbons into water vapour and carbon dioxide. Some converters also reduce harmful nitrogen oxides.

The device is mounted between the exhaust manifold and the silencer box (muffler). Upgrades include Full Cat back, Cat bypass exhaust systems and sports cats.

Basically speaking the Cat is a restrictive device in terms of performance and increased back pressure, thus robbing horsepower due to the increased work load the engine needs to overcome to expel the gases from the engine. Exhaust upgrades can help to overcome the issues caused and reasonable performance gains can be made by replacing the standard OEM equipment, but at the sacrifice of emissions.

Depending on your local legislation, this can have a impact on your car´s road legality for road driving. We are coming at this from a performance point of view, so please seek advise to make sure your operating with in the law for daily drivers.

Oxygen Sensor:

Modern fuel injected cars use a oxygen sensor to measure oxygen levels present in the exhaust, from this the programmed ECU can add or subtract fuel to obtain the correct mixture for maximum fuel economy.

A mixture is the working point that modern engine management systems employing fuel injection attempt to achieve in light load cruise situations.

For gasoline fuel, the stoichiometric air/fuel mixture is approximately 14.7 times the mass of air to fuel. Any mixture less than 14.7 to 1 is considered to be a rich mixture. Any more than 14.7 to 1 is a lean mixture- given perfect (ideal) "test" fuel (gasoline consisting of solely n-heptane and iso-octane). The oxygen sensor is mounted in the exhaust manifold or close to it in the exhaust pipe.

Silencer box/ Muffler:

The silencer/muffler box serves to reduce exhaust noises down to legislative acceptable levels. As the combustion process is a series of explosions that create a lot of noise, the silencer/muffler design uses baffles to bounce the sound waves around and cancel each other out.

Some designs also use fibre-glass packing fibres to absorbs the sound energy as the gases flow through the device. This is another restrictive device in terms of engine performance, but a well designed system will increase performance and also keep noise level to acceptable levels.

Source : rapid-racer.com/

No comments:

Post a Comment